CATEGORY

CONTACT US

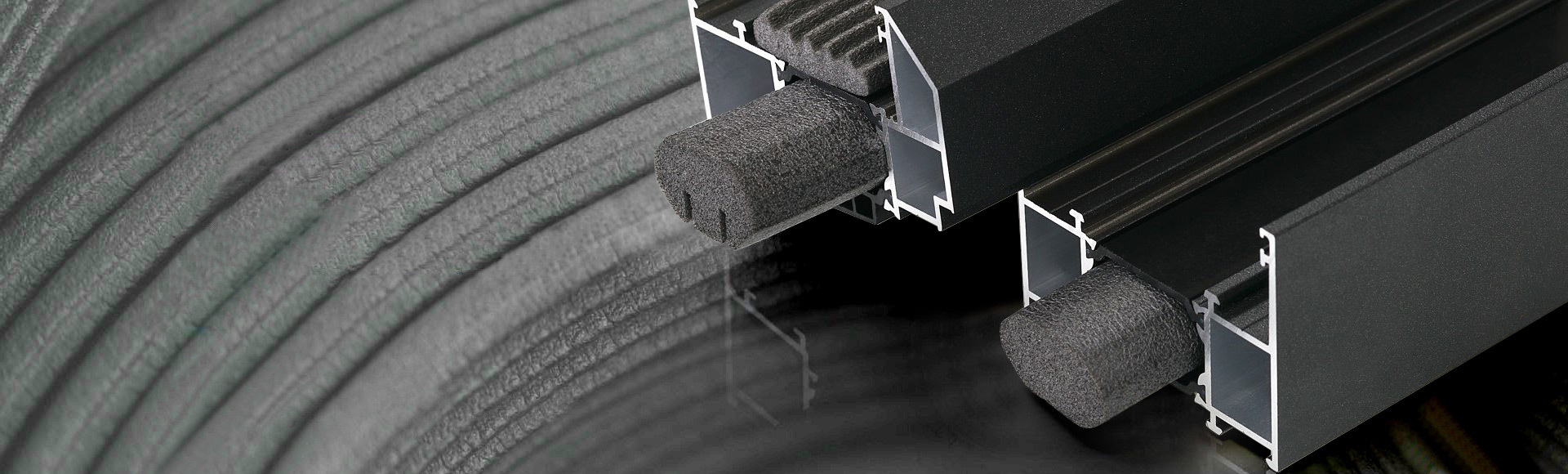

Aluminum-wood doors and Windows are compacted and foamed Wz-1001

On the basis of emphasizing the functional requirements of the product, starting from reality, we pay more attention to creating the most comfortable door and window experience, and express our understanding of sealing through design power. From a design perspective, a targeted sealing design solution is developed based on the process characteristics of the customer's product structure. By using the foam ratio of the adhesive strip and adopting different soft and hard process standards at different positions, the convenience of product installation and the best sealing stability are ensured, while the appearance design and application effect are improved to the best fit point.

On the basis of emphasizing the functional requirements of the product, starting from reality, we pay more attention to creating the most comfortable door and window experience, and express our understanding of sealing through design power. From a design perspective, a targeted sealing design solution is developed based on the process characteristics of the customer's product structure. By using the foam ratio of the adhesive strip and adopting different soft and hard process standards at different positions, the convenience of product installation and the best sealing stability are ensured, while the appearance design and application effect are improved to the best fit point.

Aluminum and wood dust-proof quiet sealing strip Wz-1032

On the basis of emphasizing the functional requirements of the product, starting from reality, we pay more attention to creating the most comfortable door and window experience, and express our understanding of sealing through design power. From a design perspective, a targeted sealing design solution is developed based on the process characteristics of the customer's product structure. By using the foam ratio of the adhesive strip and adopting different soft and hard process standards at different positions, the convenience of product installation and the best sealing stability are ensured, while the appearance design and application effect are improved to the best fit point.

On the basis of emphasizing the functional requirements of the product, starting from reality, we pay more attention to creating the most comfortable door and window experience, and express our understanding of sealing through design power. From a design perspective, a targeted sealing design solution is developed based on the process characteristics of the customer's product structure. By using the foam ratio of the adhesive strip and adopting different soft and hard process standards at different positions, the convenience of product installation and the best sealing stability are ensured, while the appearance design and application effect are improved to the best fit point.

Aluminum-wood doors and Windows are compacted and foamed Wz-1002

On the basis of emphasizing the functional requirements of the product, starting from reality, we pay more attention to creating the most comfortable door and window experience, and express our understanding of sealing through design power. From a design perspective, a targeted sealing design solution is developed based on the process characteristics of the customer's product structure. By using the foam ratio of the adhesive strip and adopting different soft and hard process standards at different positions, the convenience of product installation and the best sealing stability are ensured, while the appearance design and application effect are improved to the best fit point.

Garage/Solar/Container/Seal Strip

On the basis of emphasizing the functional requirements of the product, starting from reality, we pay more attention to creating the most comfortable door and window experience, and express our understanding of sealing through design power. From a design perspective, a targeted sealing design solution is developed based on the process characteristics of the customer's product structure. By using the foam ratio of the adhesive strip and adopting different soft and hard process standards at different positions, the convenience of product installation and the best sealing stability are ensured, while the appearance design and application effect are improved to the best fit point.

Aluminum and wood waterproof sealing strip Wz-1020

On the basis of emphasizing the functional requirements of the product, starting from reality, we pay more attention to creating the most comfortable door and window experience, and express our understanding of sealing through design power. From a design perspective, a targeted sealing design solution is developed based on the process characteristics of the customer's product structure. By using the foam ratio of the adhesive strip and adopting different soft and hard process standards at different positions, the convenience of product installation and the best sealing stability are ensured, while the appearance design and application effect are improved to the best fit point.

Aluminum and wood glass inner sealing strip Wz-1037

On the basis of emphasizing the functional requirements of the product, starting from reality, we pay more attention to creating the most comfortable door and window experience, and express our understanding of sealing through design power. From a design perspective, a targeted sealing design solution is developed based on the process characteristics of the customer's product structure. By using the foam ratio of the adhesive strip and adopting different soft and hard process standards at different positions, the convenience of product installation and the best sealing stability are ensured, while the appearance design and application effect are improved to the best fit point.

Aluminum and wood glass inner sealing strip Wz-1037

On the basis of emphasizing the functional requirements of the product, starting from reality, we pay more attention to creating the most comfortable door and window experience, and express our understanding of sealing through design power. From a design perspective, a targeted sealing design solution is developed based on the process characteristics of the customer's product structure. By using the foam ratio of the adhesive strip and adopting different soft and hard process standards at different positions, the convenience of product installation and the best sealing stability are ensured, while the appearance design and application effect are improved to the best fit point.